VACUUM METALLIZING

Vacuum metallizing creates a one-way mirror or reflective effect on the part. Metallizing is compatible with thermoformed or injection molded parts in acrylic, polycarbonate, or nylon. A mirrored coating provides the best method for concealment. For instance, in security applications, the mirrored coating conceals the camera, but does not interfere with the camera’s function. Metallized parts are available in 24KGold or 420 stainless ‘chrome’ finish. Other custom coatings are available upon request either through Criterion’s metallizing process or specialized partners.

PAINT

Vacuum metallizing creates a one-way mirror or reflective effect on the part. Metallizing is compatible with thermoformed or injection molded parts in acrylic, polycarbonate, or nylon. A mirrored coating provides the best method for concealment. For instance, in security applications, the mirrored coating conceals the camera, but does not interfere with the camera’s function. Metallized parts are available in 24KGold or 420 stainless ‘chrome’ finish. Other custom coatings are available upon request either through Criterion’s metallizing process or specialized partners.

ELECTROSTATIC DISCHARGE

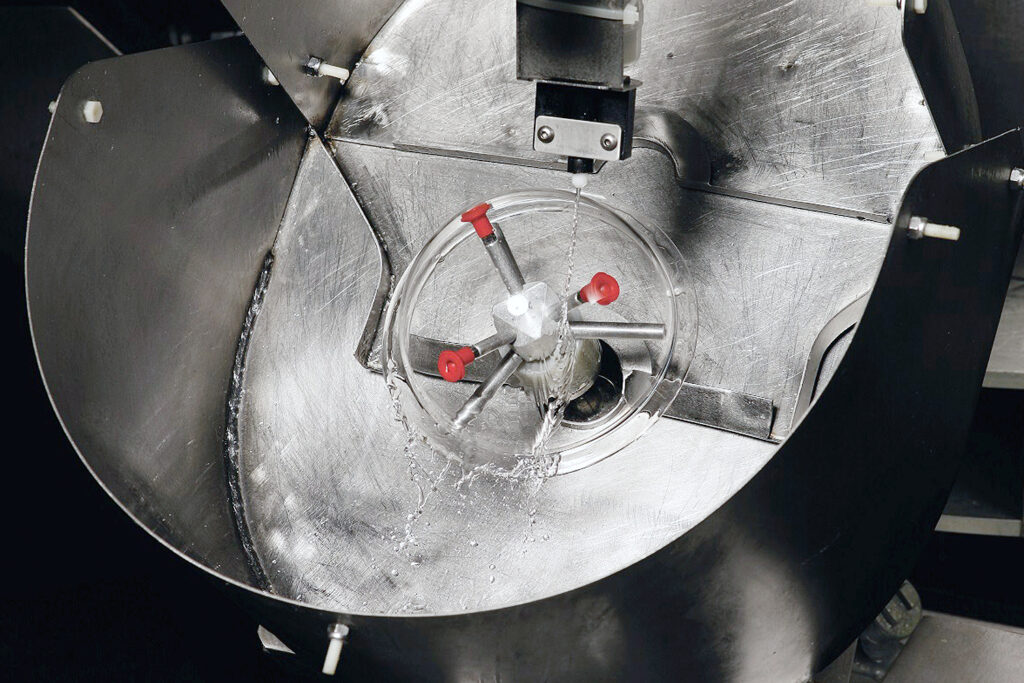

The same partners that helped develop the scratch resistant coating also developed an electrostatic discharge (ESD) coating for highly sensitive applications. Using the same custom built machines, the ESD coating is applied to the exterior of polycarbonate injection molded parts to dissipate any static charge. Other coatings are available through Criterion’s partners, for example, reflective/anti-reflective (AR) and ITO conductive coatings on shallow draw or flat windows.